Welcome to WIRA

Connecting Through Quality —

Made in Germany Since 1976

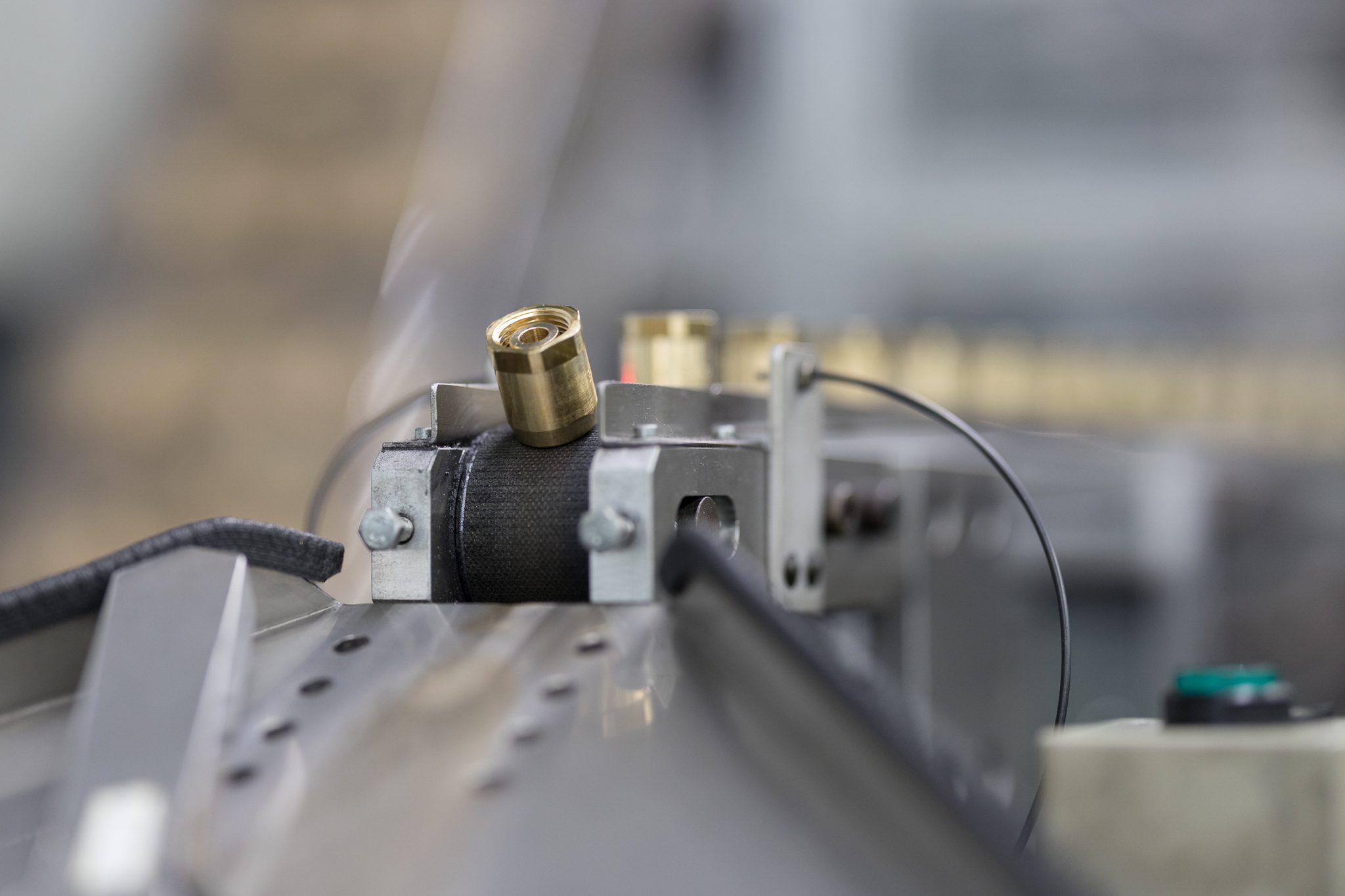

WIRA stands for high-quality Push-in Fittings, Cutting Ring Systems, and Manifolds. We produce ready-to-install compressed air fittings in OEM quality. A comprehensive range of over 7,900 products, consisting of tube and hose connections as well as CNC turned parts, makes us the preferred partner for commercial vehicle and agricultural technology manufacturers as well as the spare parts trade. You too can rely on our connection solutions for compressed air systems – "Made in Germany".

Over 7,900 Products for Your Compressed Air Application

Plug-and-Play Solutions

for Your Application.

Ready-to-install pneumatic components from stock or customised: Modern CNC production in Germany and over 45 years of experience guarantee the highest quality, even for customised designs.

Proven Quality and Reliability

Certified Quality Through Strict Audits

Our products have been subject to external audits for more than three decades. Independent testing institutions such as TÜV Rheinland confirm that we fulfil the highest quality and environmental protection requirements. This allows reliable and uncomplicated use in various areas of application – for example in commercial vehicles and mobile machinery.

We're here for you

Investment in People and Machines

Unwavering corporate principles ensure high customer satisfaction, competitiveness and quality. Continuous investment in the development of our employees and modern production lines ensure that our quality products meet or exceed the ever-changing requirements of the automotive industry. By investing in digitalisation and sustainability, we stay ahead of the curve and strengthen effectiveness and environmental compatibility.

Unlimited Variety of Applications

Customised Production

In addition to thousands of tried-and-tested standard products, we also manufacture customised items that meet customer-specific requirements. Do you need customised products in small(est) batch sizes? Then we're your ideal partner! Realise untapped potential and invest in maximum reliability and quality.

Contact Form

We Are Here for You!

What challenges do compressed air connections have to overcome in your application? Our experienced experts will work out the best technical and economical solution for you.

WIRA

Fahrzeug- und Maschinenteile GmbH

Alte Papiermühle Hämmern 8

51688 Wipperfürth

GERMANY

Mon – Thu: 08:00 – 16:30

Fri: 08:00 – 16:00

Stay Informed!

Latest News from The WIRA Blog

Our blog offers informative articles on new products, innovations, industry trends, application examples, sustainability, cost reduction and efficiency improvement, quality management, certifications, research and development, maintenance and servicing, occupational safety, digitalisation and mechanical engineering 4.0 as well as inspiring case studies and success stories.

The latest economic forecast from the Ifo Institute offers hope for an economic recovery in Germany. By raising its growth expectation to 1.5% for the year 2026, the renowned economic institute is sending a clear signal: the upswing is coming. For us at WIRA Fahrzeug- und Maschinenteile GmbH, this is more than just good news – it confirms our strategic course and opens up new opportunities in our core industries: the automotive and mechanical engineering sectors.

In a globalized world where supply chains often span across continents, we want to make a clear statement: WIRA sources its materials exclusively from partners within Europe and consciously refrains from maintaining direct business relations with the USA. This decision is deeply rooted in our corporate philosophy and reflects our commitment to quality, sustainability, and regional responsibility.

In a globalized world where supply chains often span across continents, we want to make a clear statement: WIRA sources its materials exclusively from partners within Europe and consciously refrains from maintaining direct business relations with the USA. This decision is deeply rooted in our corporate philosophy and reflects our commitment to quality, sustainability, and regional responsibility.

WIRA can once again look back with pride on a significant milestone: In 2025, the company has once again successfully completed the audits for the internationally renowned standards IATF 16949 and ISO 14001.

Trump’s tariffs have global impact: WIRA feels indirect effects through rising raw material costs, disrupted supply chains, increased competition, and global uncertainty.